Description

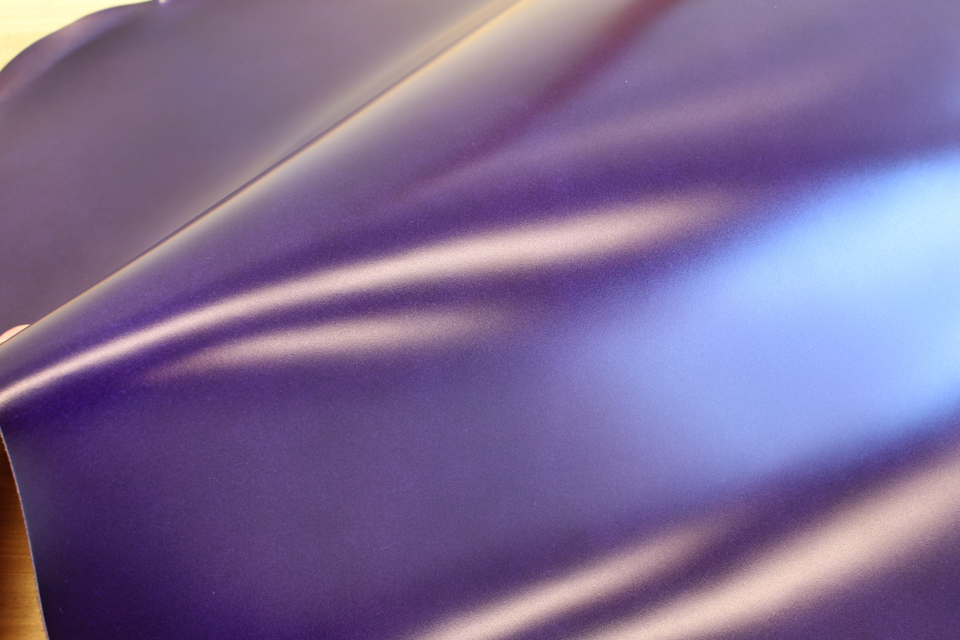

Blue Cordovan Leather Shells 1-1.2mm/2-3 oz

A deep and rich blue will provide a good color contrast to your project or create a more soothing tone or business-like feel.

A deep and rich blue will provide a good color contrast to your project or create a more soothing tone or business-like feel.

| Weight | 16 oz |

|---|---|

| Dimensions | 25 × 20 × 1 in |

| Cordovan Leather Cuts | 8 DS (Half-Shell), 9 DS (Half-Shell), 10 DS (Half-Shell), 11 DS (Half-Shell), 12 DS, 13 DS, 14 DS, 15 DS, 16 DS, 17 DS, 18 DS, 19 DS, 20 DS, 21 DS, 22 DS, 23 DS, 24 DS, 25 DS, 26 DS, 27 DS, 28 DS, 29 DS |

These meticulously produced, genuine cordovan shells are for leatherworkers who want to make heirloom-quality goods. You will be amazed by the quality and craftsmanship. The hides are polished to such a high degree that you can see your reflection in their surface. Many US leathercrafters have probably not heard of Leder Ogawa, but their leather quality has made them a well-known and trusted supplier in Japan. We have partnered with Leder Ogawa to become a US supplier of their leathers. These Cordovan Shells feature:

Horsehide, sustainably produced, is a rare leather. Even rarer is cordovan. Only certain types of hides have the right qualities to become cordovan. Even within these strict criteria, only 10-15% of one entire horsehide is usable as shell cordovan.

Leder Ogawa has been finishing shell cordovan for 50 years. They are a unique, small company focused solely on improving cordovan shell quality. The company sources cordovan hides from meat by-products in countries like France, Spain, and Poland. You can rest assured that they use every part of the animal in addition to the raw leather material.

This Shell Cordovan is 100% vegetable tanned at the renowned tannery Shinki Hikaku. After initial tanning, these pieces transfer to Leder Ogawa, where each pair of shells are individually oiled and dried to achieve the right treatment balance. According to many factors, they calibrate this process, including the raw material’s thickness, size, and even the ambient temperature and humidity.

The grain on cordovan stands up vertically, which is different from regular leather with a crisscross pattern (think grass vs. woven mat). This structure gives the shell a greater depth and clarity of color and surface quality. The inside of the raw leather is actually the top side of cordovan; what is the flesh side of other leathers. This unique phenomenon of cordovan makes the inside the eventual dyed and finished side.

Although the shells are thinner than, say, harness, they have a firm temper. They do not drape like garment leather and will maintain their shape if properly molded. Like all firm tempered leather, we do not advise bending the leather in opposite directions, back and forth. This bending will eventually introduce breaks and cracks, though cordovan will resist this much more than other leathers.

This selection of cordovan shells is optimized for leather goods. They have a firmer temper than other comparable shells. They have been pressed to compact the grain to give a higher density to the material. This is different from cordovan optimized for shoes; they are stretchier and have a lower density fiber makeup.

Per Leder Ogawa’s recommendation, you can still make shoes from this type of cordovan but extra care must be taken at the toes and where the shoe is stretched over the last. If you are interested in cordovan more optimized for shoe-making, please contact us via email.

Cordovan’s strength and value come from its durability and ease of maintenance. You can shine a worn pair of cordovan shoes to look almost new. As mentioned above, cordovan does a great job of resisting cracking where it continuously bends (like at the shoe’s break). This break is where the toes section bends when you take a step. Cordovan shoes will remain smooth even after years of use. Similar durability applies to cordovan wallets, bags, and other items.

The smooth, shiny surface of cordovan can take scratches and scuffs. You can easily buff out these wear marks with regular maintenance.

We offer cordovan shells at an average thickness of 1.2mm / 3 oz. This thickness is great for smaller items and, when combined with a lining leather, makes an excellent choice for projects of any size.

Shells are sold by the square decimeter (DS). A decimeter is 1/10 of a meter. 1 square foot equals approximately 9.3 DS. We offer full and half-shells. Half shells are cut across the long side of the shell.

Leder Ogawa cordovan is famous for its color. They have a unique process of using full aniline dye to produce bright, vibrant colors unmatched by other producers. Like all full aniline leathers, the hides are a simple combination of leather and dye. There are no pigments or fillers added; you are using the natural surface of the leather. Lighter colors reveal the natural variation of the underlying leather color. This quality gives a marbled look to the surface. This cordovan’s surface quality is shiny and can be polished to a mirror finish.

$143.00

$143.00

Join our newsletter and get our free guide on How a Luxury Bag Component Is Made.

Though our cousins are from Hawaii, we hate spam and will never send it to you.